A warehouse may be defined as a place for storing goods that will be sold or distributed later. Warehouses are basically used by the manufacturer, importer-exporters, customs, transport businesses, etc. Generally, warehouses are designed for the loading and unloading of the goods directly from railways, airports, seaports. Warehousing is a requirement for most businesses that manufacture, import, export or transport goods. A warehouse provides a centralized location for goods, making it easier to track and manage inventory. Also, the right anti-slippery warehouse floor coating ensures that nobody falls or trips down while walking down the warehouse or the commercial place.

Floor Coating and Why Is It Needed for A Warehouse?

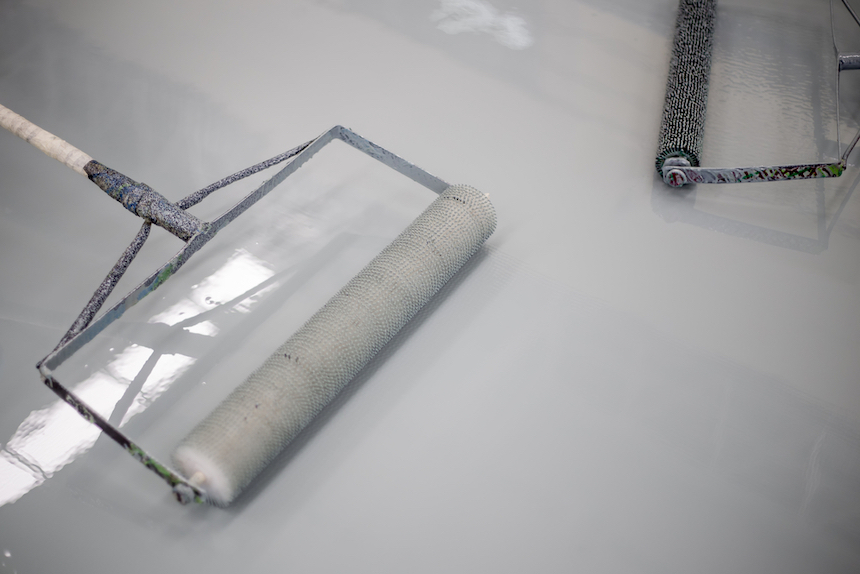

Literally Floor-Coating is the general term for a strong, protective, efficient layering on the floor where damage is expected including warehouses, chemical plants, and manufacturing floors. Floor-coating can also be used to brighten or define areas of facilities, cover stained concrete, etc. There are a lot of terms for floor coating types, some referring to the material, some to the uses or benefits. For example, Epoxy floor coating types, and Chemical resistant floor coatings are not mutually exclusive. You should always choose coatings that will not be affected by chemicals or spellings. Aesthetics and design of the floors are some of the top priorities that you must have regarding the overall selection of the floor coating.

What Is Warehouse Floor Coating?

Relatively warehouse floor coating is more beneficial than just paint. Compared to other capabilities and equipment necessary in creative warehouses or other manufacturing settings, the paint preferred to coat a concrete whereas, warehouse floor coatings shield the material from harmful spills and heavy abuse, increase the efficiency level. A warehouse floor coating system can repair such as dusting of vacant concrete, cracks, and joints.

Warehouse Floor-Coating Types

A complete and ideal flooring system for the warehouse will exhibit a level, smoothness, long-lasting, easy to fair finish. It will also provide a permanent solution to the facilities the floor needs. Epoxy and urethane are the most used due to their many benefits. Generally, polyurethane floor coating is highly flexible and elastic, where epoxy floor coating is harder and more breakable. Urethane and Epoxy are great for protecting your floor against the damage, stains, oils, and chemicals.

Benefits of Warehouse Floor Coating

- Enhancing safety, efficiency, and aesthetics with warehouse floor coatings. In settings where heavy racks are used the proper warehouse floor coating can handle, protect concrete from cracking and chipping as well as the harmful effects of spilled chemicals. Here are a few key beneficial elements of warehouse floor coatings including durability, strength, aesthetics, maintenance, and safety. Coatings also protect people; workers can move more safely on floor coatings. The. advantages and disadvantages of the many available coating systems mean decision-makers must assess the work done in their spaces, the safety concerns present in those settings, their project budget, and time constraints.

- When the goods are stowed in warehouses, they are wide-open for many risks in the form of deterioration, theft, exploration fired. Warehouses are basically constructed in such a way as it can handle such risks.

- A warehouse creates time utility by bringing the time gap between the production and the consumption of the goods. It helps to make available the goods when it is required or demanded.

- Warehouse floors can stand up to any harshest situations.

- Low maintenance

- Chemical resistant

- A Fine, smooth and beautiful appearance

- Temperature resistant

You can now go for MMA certified coatings which have low glare methyl methacrylate are resistant to certain forms of alkali and acidic reactions that can corrode the layers of the floor. Needs for warehouse arises also because some goods are produced only in a particular season, but the demand goes on throughout the entire year. Equally the warehouse floor coating is formed throughout the year but required only for an exact season.

- Eye Test Camps To Treat All Kinds of Optical Problems - March 18, 2021

- 6 Tips To Choose the Best Firm for Civil Constructions in Your City - February 17, 2021

- Five Best Landscape Design Ideas to Try in 2020 - July 11, 2020